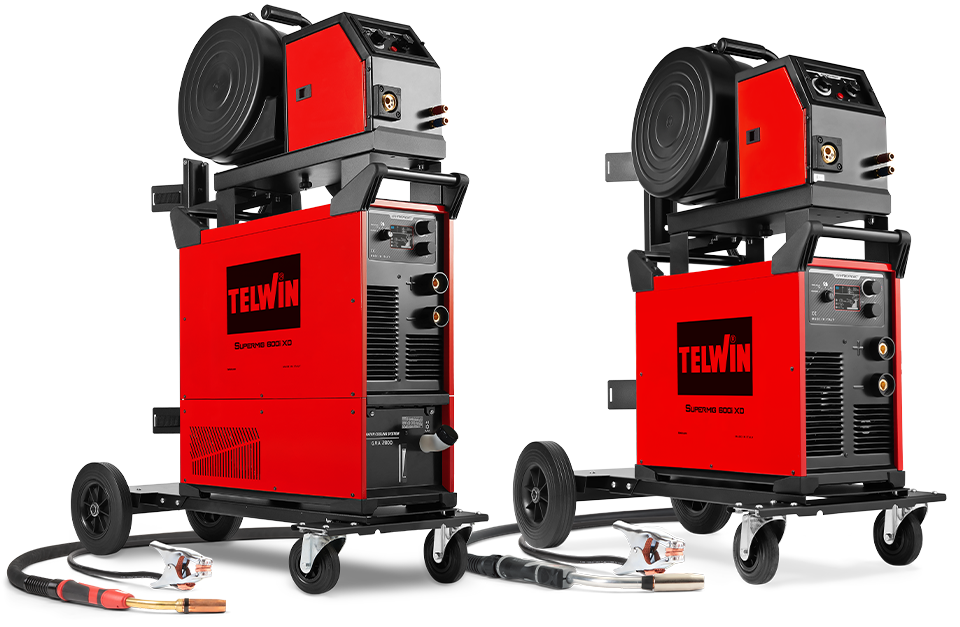

Supermig 600i XD

EVEN HIGHER PERFORMANCE

The range of MIG-MAG / FLUX / BRAZING / MMA / TIG DC-LIFT / GOUGING multiprocess inverter welding machines is enriched with the XD models: high duty cycle for continuous processing and particularly demanding applications.

SUPERTIG 302 AC/DC AQUA

TIG AC/DC (HF or LIFT), TIG PULSE (PULSE and EASY PULSE) and MMA inverter welding machine

The ideal machine for the professional looking for the right balance between performance and versatility of use without compromising on the quality of the results.