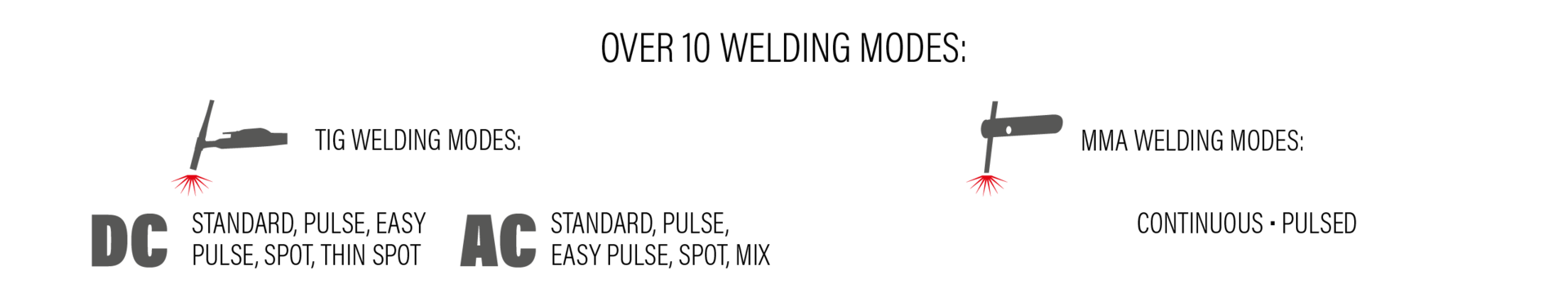

TIG AC/DC (HF or LIFT), TIG PULSE (PULSE and EASY PULSE) and MMA inverter welding machine.

Use of different types of materials, such as steel, stainless steel, aluminium, titanium, copper, nickel, magnesium and their alloys.

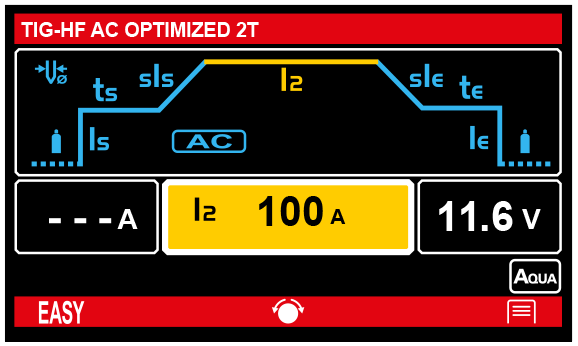

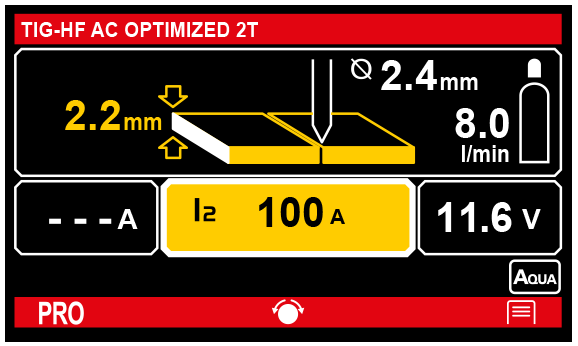

The WAVE OS system simplifies welding operations (EASY mode); customisable based on user requirements (PRO mode); traceable and analysable by saving data via USB.

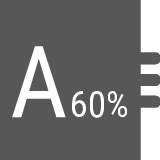

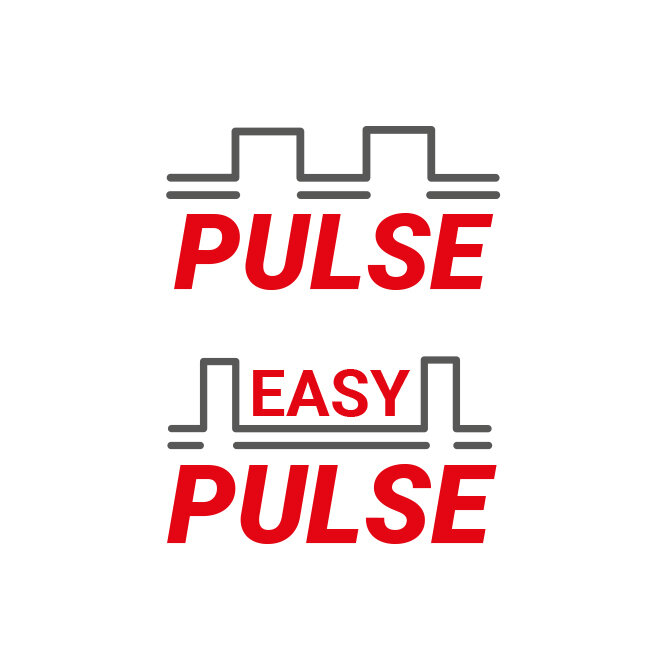

Designed to ensure excellent results on every thickness even the thinnest, the PULSE mode (also in the EASY PULSE version) reduces material deformation ensuring high arc stability.

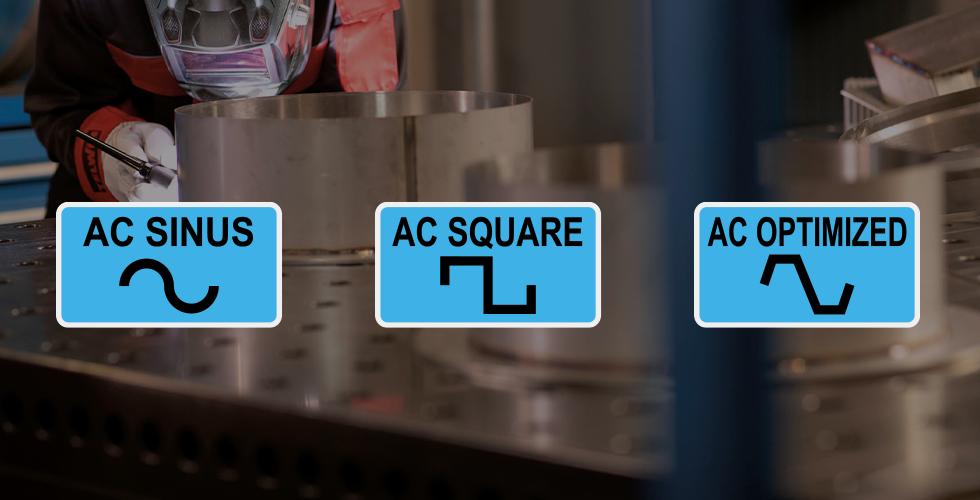

Numerous advanced functionalities for TIG welding: THIN SPOT (DC) for precise and clean spot on thin surfaces; MIX AC-DC for heating the workpiece to be welded and preparing it for AC welding; selection of different waveforms (Sinusoidal, Square, Optimised) for AC welding according to machining needs.

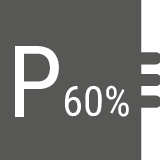

Electrode welding both in continuous and pulse mode (MMA Pulse) which ensures excellent results with basic electrodes and in position welding.

Designed to ensure reliability over time, it features a dedicated air tunnel cooling system that protects against dust and dirt.

The solid and robust construction ensures durability even in challenging work environments.

Features:

TIG

- Setting of the work environment closest to your needs: EASY with automatic parameter setting choosing the material and thickness of the workpiece; PRO with customisation of all individual TIG welding parameters to create custom programs to save and recall at any time;

- pulse and pulse EASY operation; in 2/ 4 times, Bi-Level;

- more than 10 welding modes in TIG;

- selection of 3 different waveforms in AC: Sinusoidal, Square, Optimised;

- Advanced functions: THINSPOT for welding very thin sheets, in manual or repeated cycle mode; MIX AC-DC for heating the workpiece to be welded and preparing it for AC welding;

- start (HF/LIFT) at optimised minimum current;

- automatic recognition of the cooling unit;

- provision for remote control and cooling unit;

- compatibility with PRO torches.

MMA

- direct and pulse current (MMA PULSE) operation;

- hot start, arc force adjustments;

- anti-stick protection;

- VRD device;

- welding voltage and current display.

Other features:

- Wave OS operating system;

- USB output to download production data and software upgrades;

- reliability over time thanks to dedicated air tunnel cooling system that protects against dust and dirt;

- ensures the best performance even with undervoltages (up to -25%) and overvoltages (+ 15%);

- automatic voltage detection of the power supply network (multivoltage);

- modular design to speed up assembly and maintenance operations;

- solid and robust construction for use in any working environment;

- thermostatic protection, protection against overvoltage, undervoltage, internal dirt, overcurrent, phase failure, cooling unit liquid.

Supplied with TIG welding accessories, cooling unit and trolley.