MIG-MAG/FLUX gas shielded/BRAZING/MMA and TIG DC-Lift multiprocess inverter welding machine, with external 4-roller wire feeder.

Flexible use with different materials (steel, stainless steel, high-strength steels, aluminium, galvanised sheets, etc.) and a wide variety of applications (industry, maintenance, installation, metalwork, construction, etc.).

The rapid SYNERGIC adjustment of welding parameters, thanks to ONE TOUCH SYNERGY technology, makes the product very easy to use.

Intelligent, automatic arc control, moment by moment, maintains high performance in all working conditions, with different materials and/or gases. It is also possible to manually adjust the arc length: this adjustment allows the shape of the weld bead to be modified according to the welder's style.

The ONE TOUCH LCD graphic display allows for better reading of all welding parameters.

Telwin ATC technology makes it easy to achieve excellent standards of welding on thin materials thanks to state-of-the-art control of the arc.

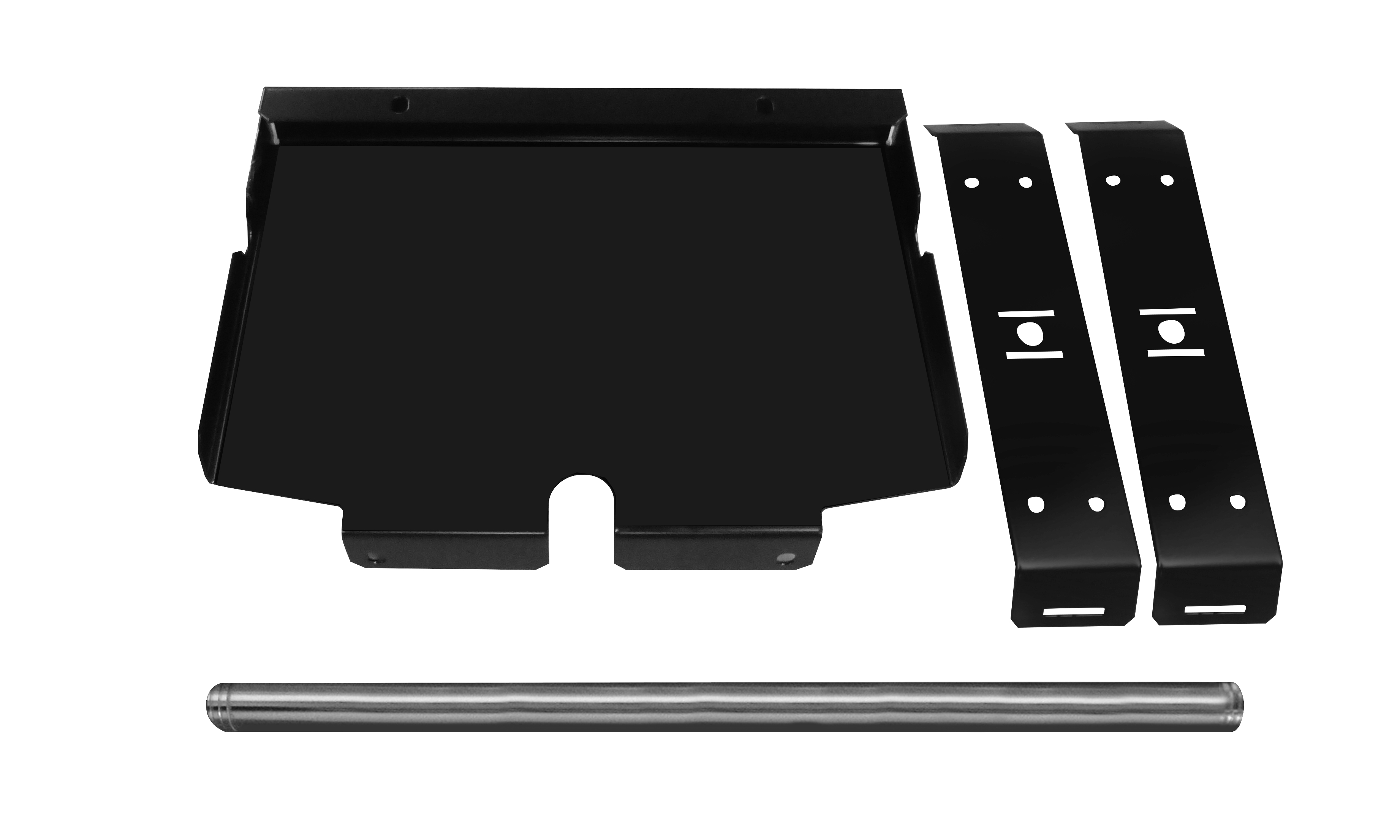

The professional 4-rolls wire feeder is designed to ensure precise and constant wire feeding, even in continuous industrial applications with high duty cycles. Robust and ergonomic, with reel support up to 300 mm, internal lighting, IP protection and compatibility with air/liquid torches, it ensures reliability, versatility and resistance in harsh environments. It allows remote adjustment of all welding parameters.

Interchangeable cable harness.

Features:

- robust and impact resistant;

- compact and ergonomic structure;

- high energy efficiency and low consumption;

- backlit LCD display.

MIG-MAG

- operating modes: manual and synergic;

- 40 pre-set synergic curves;

- Possibility of creating, saving and retrieving customised welding programs;

- LCD display showing wire speed, voltage and welding current;

- selection of 2/4-stroke operation, Bi-Level, spot, material thicknesses in inches and millimetres;

- adjustments: wire up slope, electronic reactance, wire burn-back time, post gas;

MMA

- MMA adjustments: hot start, arc force;

- anti-stick protection;

- VRD device;

- display showing voltage and welding current.

TIG

- LIFT DC striking and display of welding voltage and current.

Thermostatic protection, overvoltage (+15%), undervoltage (-15%), overcurrent, motor generator.

Complete with MIG-MAG torch, cable and earth clamp, wire feeder, connection cables and water cooling unit.