Products

PPE & Safety

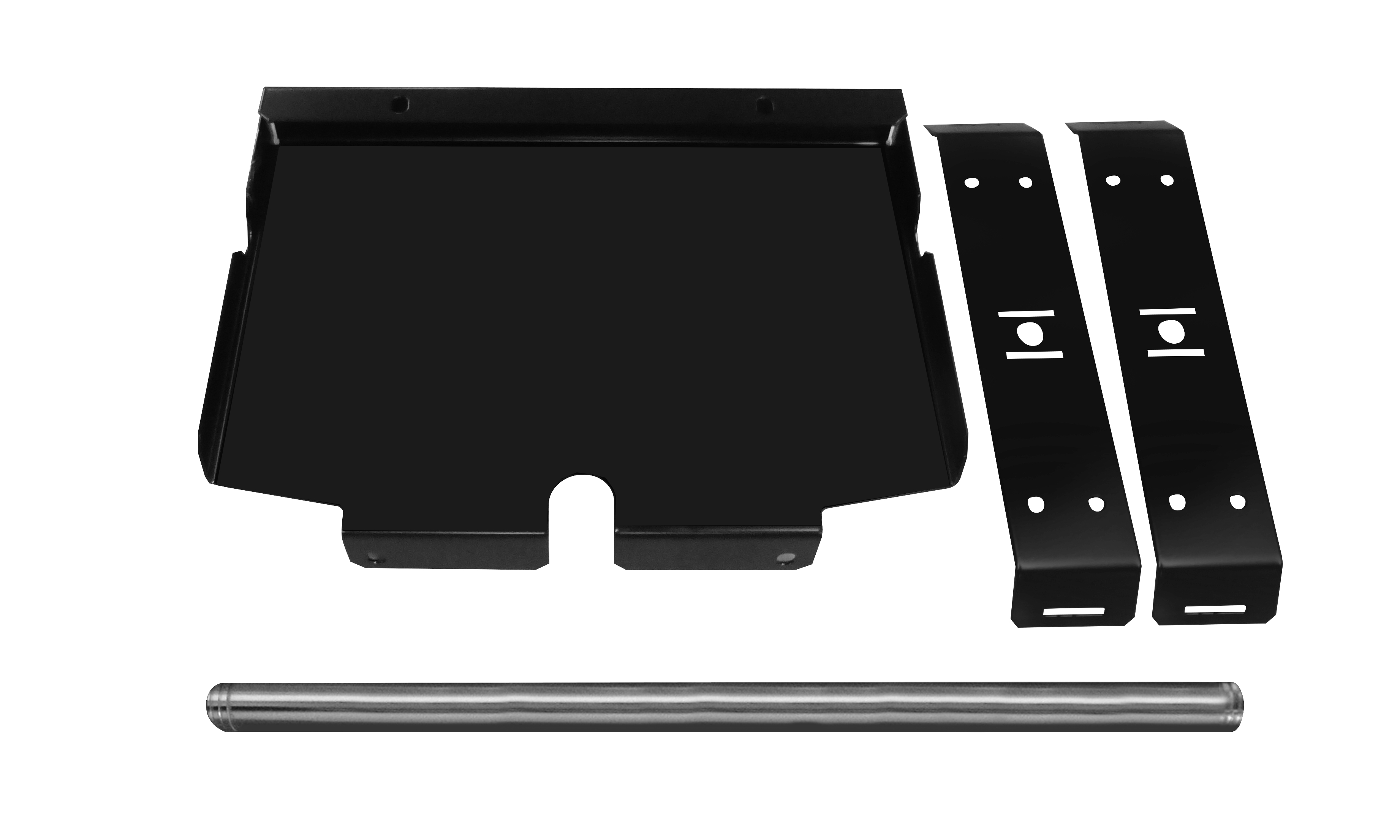

Accessories and Consumables

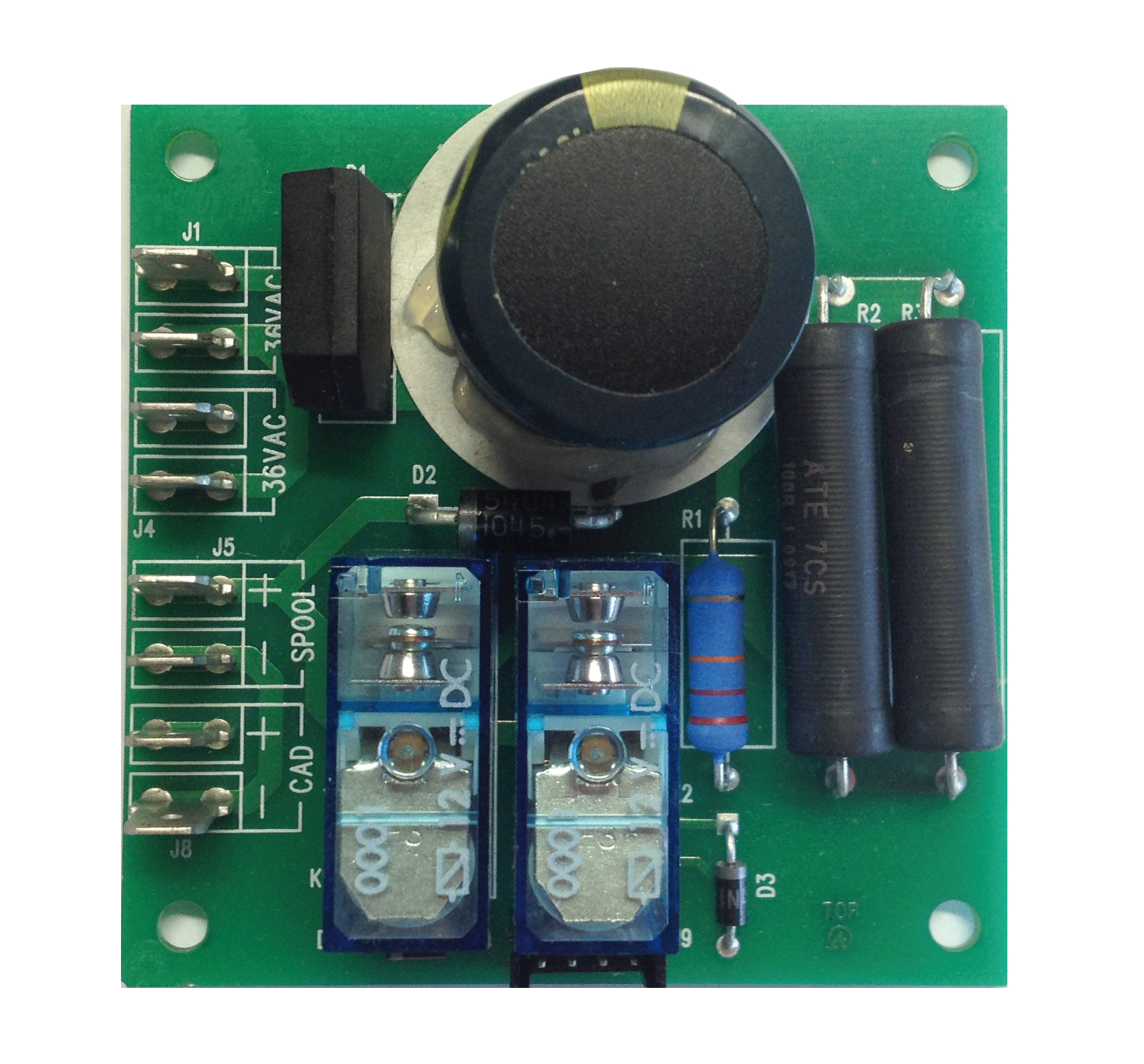

Supermig i

Discover more

Products

Industries

SMART REPAIR

Discover more

Need more help?

Contact us

Corporate

Knowledge Center

JOIN THE INNOVATION

Who we are