Professional wire feeder unit designed to ensure accurate and stable wire feed in MIG-MAG welding applications. Thanks to its robust construction and integrated technologies, it is ideal for industrial environments that require operational continuity and maximum efficiency.

The unit supports coils up to 300 mm in diameter, offering flexibility for use with different types of wire. The side loading system facilitates reel change, reducing machine downtime. The wire feed is managed by a 4-roller system with kinetic spool brake, which ensures constant and uniform feeding, minimising the risk of slippage or interruptions in the feeding process. The feeding area is equipped with internal lighting, which improves visibility during replacement and adjustment operations.

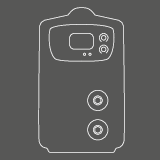

The user interface is characterised by an LCD display with synergic parameter adjustment, which allows simple and intuitive management of welding settings. The presence of OneTouch technology allows automatic optimisation of working parameters, simplifying the process and reducing the operator's margin for error. There are also two buttons for wire feed and gas outlet.

Designed to withstand the most demanding work environments, it features an ergonomic and balanced handle for easy transportation, while the optional wheel kit allows for better mobility within the work area.

The unit is compatible with air-cooled and liquid-cooled torches, offering versatility in different welding applications. It also features optimised connections for integration with dedicated cable bundles, ensuring stable and secure connectivity with the welding generator.

Designed to operate with high duty cycles, it enables continuous machining at high currents without compromising performance. The feed motor is adjustable within a wide speed range, offering maximum precision in wire feeding.

Finally, thanks to its IP protection class, the unit offers high resistance against dust and water splashes, making it suitable for even the harshest working environments.

With its combination of synergetic technology, ergonomics and robustness, it is an ideal solution for professional and industrial welding needs, offering high performance, ease of use and maximum reliability.