Products

PPE & Safety

Accessories and Consumables

Supermig i

Discover more

ELECTRODE HOLDER + CABLE 35MMQ 4M AX50

804124

RC-20 10 M CONTROL 2POT

802336

FPC-200 10 M FOOT CONTROL

804456

QUICK GAS CONNECTOR

804208

ST18A PRO-C 4M AQUA AX50 8P TIG TORCH

743038

ST18A PRO-C 8M AQUA AX50 8P TIG TORCH

743040

ST18A PRO-P 4M AQUA AX50 8P TIG TORCH

743034

ST18A PRO-P 8M AQUA AX50 8P TIG TORCH

743036

COOLANT FOR COOLING SYSTEMS

802976

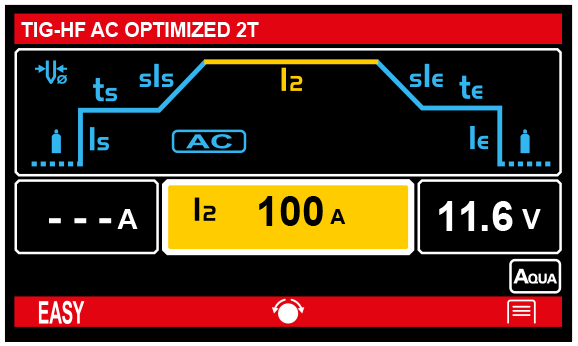

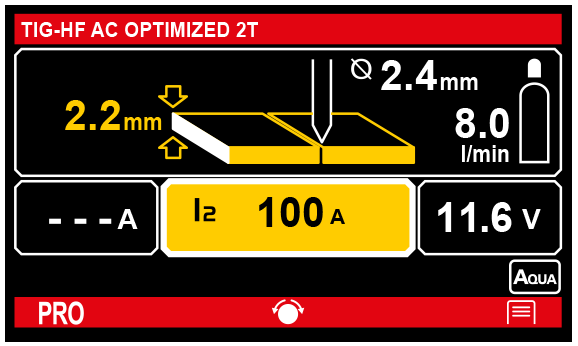

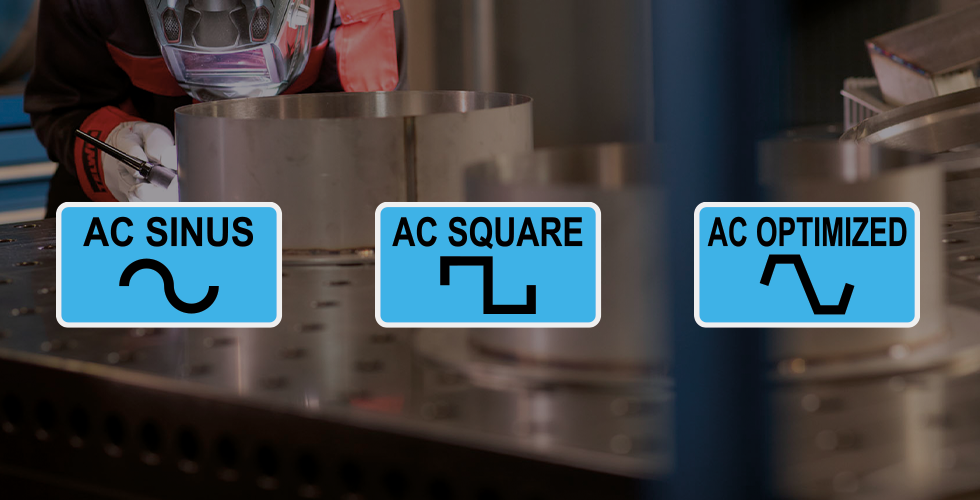

It is possible to select different waveforms for AC welding according to the processing requirements.

Choosing between Sinus, Square or Optimized wave you get different arc stability and noise reduction.

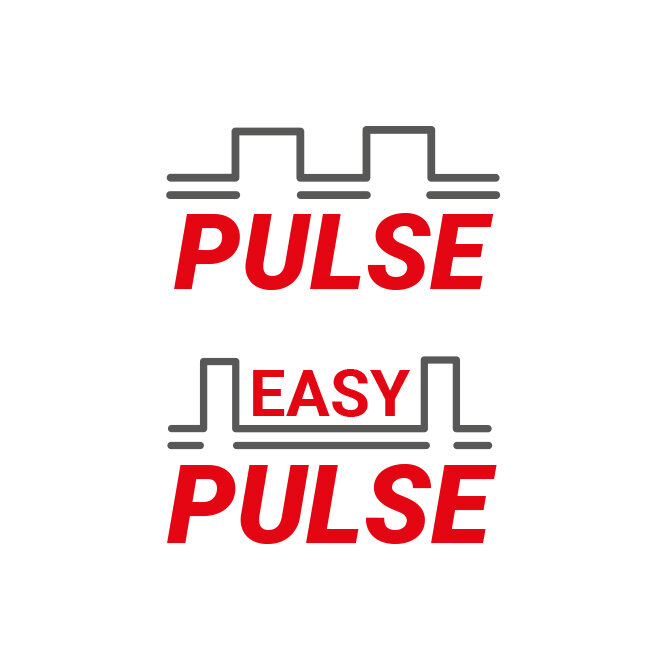

This model operates in both pulsed (PULSE) and facilitated pulsed (EASY PULSE) modes, ideal for applications on thin thicknesses or easily deformable materials, using optimized minimum current arc strike (HF/LIFT).

ThinSpot is an advanced function that allows spot welding in TIG of thin sheets in an easy, precise and rapid way. Particularly designed for working on stainless steel, it can also be used on Steel and Titanium.

Function designed to heat the piece to be welded and prepare it for AC welding. It alternates current phases in AC to others in DC. It is particularly useful when working on thicknesses or pieces with large masses.

Pulsed mode ensures excellent results with basic, cellulosic electrodes and in positional welding. It is possible to set the two pulsing currents and their times for a reduced heat input and better arc control. Less spatter and rework, higher welding seam quality.

Oops! You can compare only products of the same category

Reached the maximum number of comparable products.